Benefits of Advanceed production planning and scheduling

- Immediate Return on Investment.

- Improve Planning and Scheduling Accuracy.

- Higher productivity and reduced inventory and production cost.

- Improve Overall Equipment Effectiveness and Reduce Machine Downtime.

- Fast scheduling with an interactive and graphical planning, for visibility across the organization.

- Improvement of On-time Deliveries and Customer Service.

- Better Planning and strategic decision making thereby bringing more customer statisfaction.

Production Planning & Scheduling

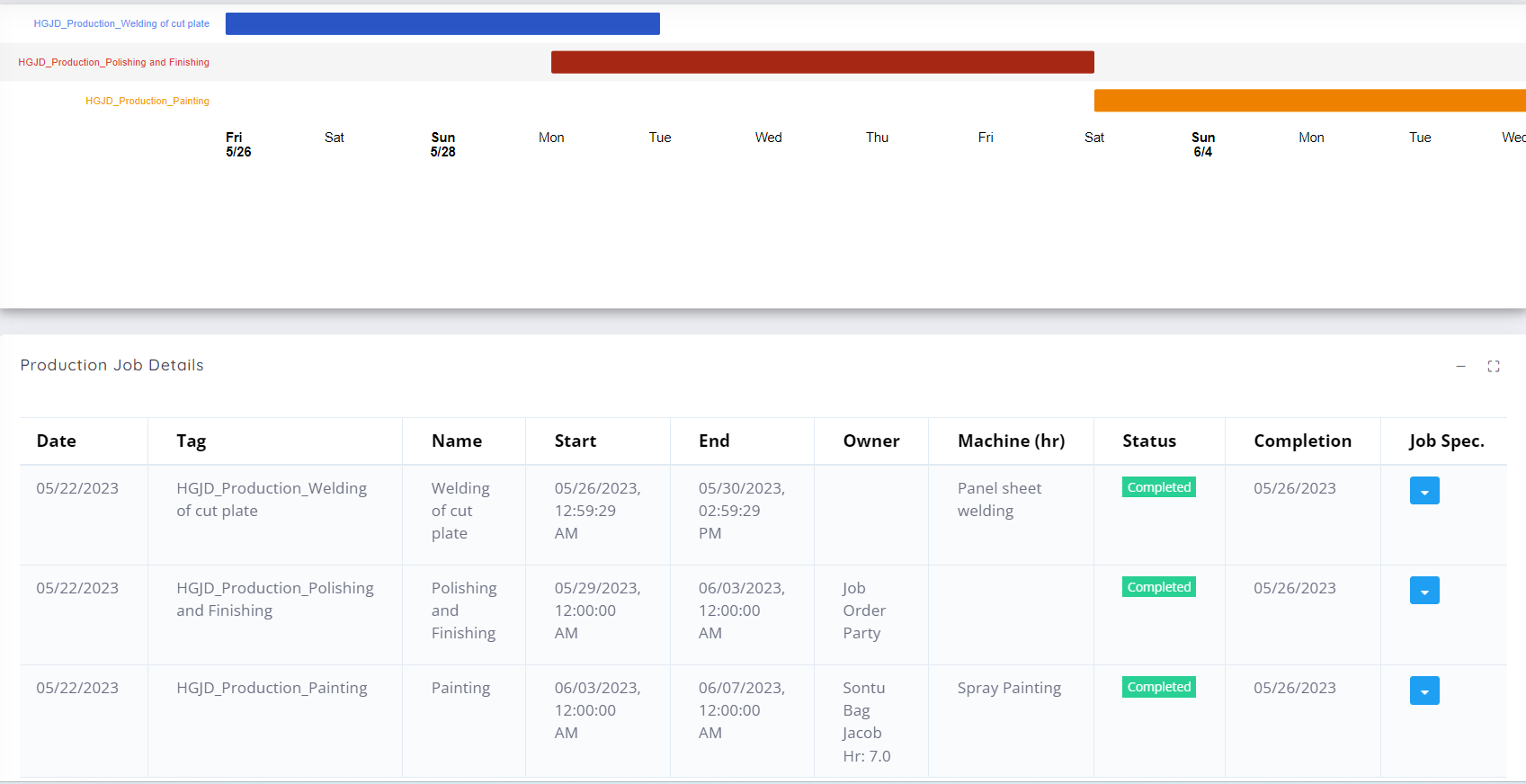

Material requisition and Production Planning is done before final schedule is created with machine, labour and RM. With the start of production, jobs are created. User can follow, update and manage the job tasks till it is completed. Production Schedule is created from Work Order on the condition that routing process of the FG is already made into the system. Planning involves the proper configuration of manufacturing plant, shift timings and machines, labours etc.

Read more on Production ERP Features

Advanced Production Scheduler

Each machine and tools are configured for a set of routing/job processes. Similarly each company employees/production supervisors, owners are also configured

for similar production processes.

The production plan consists of start and end timings of each batch job, allocated machine and or labours.

Based on availability and capacity of machines and labours already planned for previous production schedules, next schedules are automatically found out by the

advanced production scheduler (APS) modules of Peacksoft ERP.

Production planner creates planning record of the currently selected work orders with scheduled start and end date and suggests the feasibility of production delivery within

customer delivery date. It also creates production jobs with their start and end dates.

User can check and verify with customer delivery date and proceed with finalizing this plan

into confirmed schedule of production.

Software also gives option to suspend/delay/resume suspended production schedules so as to accomodate the current work order schedule within customer delivery date.

If user accepts the software scheduler suggestion, work order release and required date can be adjusted/modified from the planner.

User can override manually the software suggested production start date while creating final production schedule. Production end date will be automatically determined from this new

start date based on complete production cycle time times the batch finished good quanity.

Batch Production Planning

This helps user select multiple work orders one at a time and helps create multiple planning schedules in a batch. User can check out and confirm those schedules which are possible

within work order release dates.

Some of the schedules can be taken for further planning later from this batch schedulers. Multiple work order can be converted from planning schedules

to confirmed schedules.

Software also supports the adjustment of any kind (delay or early shifting) into any schedules making changes in all other schedules which are linked to any given machines in a cascaded

way.

Peacksoft ERP supports a drag and drop based rescheduling planner where user can shift the timing of any scheduler which in turn adjusts other schedules as per resource availability.

Capacity Production Planning

When work order needs to be scheduled and production be completed within required date, capacity addition of machines and labours are essential. The software will suggest the number of

capacity addition of machines to be made from a prescribed date.

User can add those resources in house as part of it's own capacity addition or can out-source those jobs meant to be completed

by the similar machine resources.

Production Planning Rescheduling

Production Plans can be delayed by certain finished good quantity or number of hours as the process goes on. The system will automatically adjusts the scheduling end date of currently

running Job tasks as well as all the job tasks which are scheduled to start in the same machine. It has a cascading effect of other successive tasks which are running in other machines.

So any production can be suspended or stopped for certain amount of hours, and when rescheduled, job tasks which were scheduled and not in WIP, will be rescheduled as per the current availability

of machines and labours.

Machine Job Schedule

Software will show the user machine wise jobs scheduled in future date and time. It has the details like Job card, start and end time, machine job interval delay and sequence of their operations.

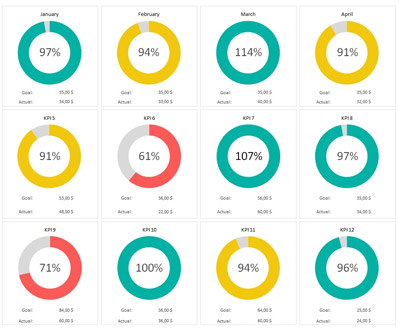

Production Reports And Analytics

Peacksoft ERP shows extensive reports and analysis on production job schedules, machine and operator wise item completion, machine wise job schedules for the scheduled Jobs. It also shows analytics of machine and operator efficiency, Production wise OEE.

Production Schedule Gantt Chart

Peacksoft ERP shows gantt chart for all the scheduled productions with the jobs in waterfall view.

Get Started with Peacksoft ERP Today

Intuitive solutions on cloud with integrated features like Accounting, Purchase, Sales, Production, CRM, Payroll, Inventory & Filing of all compliances. . Call us at +91-86608 58802 (M: 9845167247) to schedule a consultation.

Manage sales through quotation by updating information and proceed to Sales order, Sales delivery , Sales invoice by click of few button.

Manage sales through quotation by updating information and proceed to Sales order, Sales delivery , Sales invoice by click of few button.

Manage Purchases through order by updating information and proceed to GRN, Purchase Invoice by click of few buttons.

Manage Purchases through order by updating information and proceed to GRN, Purchase Invoice by click of few buttons.

Comprehensive Inventory management features for small and mid size companies.

Comprehensive Inventory management features for small and mid size companies.

Manufacturing

Manufacturing