Inventory Control & Management

Inventory Management, also called stock control, is the process of ensuring the right amount of supply of stock is available in an organization.

With the appropriate internal and production controls, this ensures the company can meet customer demand and fulfills financial obligation.

An integral part of inventory control is supply chain management (SCM), which manages the flow of raw materials, goods and services to the point where the company or customers consume the goods.

Warehouse management also falls into the arena of stock control. This process includes integrating product coding, reorder setting and reports, all product details, inventory lists and counts and methods for storing.

Warehouse management then synchronizes sales and purchases to the stock on hand (QOH).

Inventory Control Methods/Procedure

1. Choose a Management Improvement Methodology:

Management improvement methodologies involve more than just inventory control. You can improve your business, from top to bottom, with a management methodology that you commit to like Kaizen, Lean and Six Sigma.

2. Optimize Purchasing Procedures:

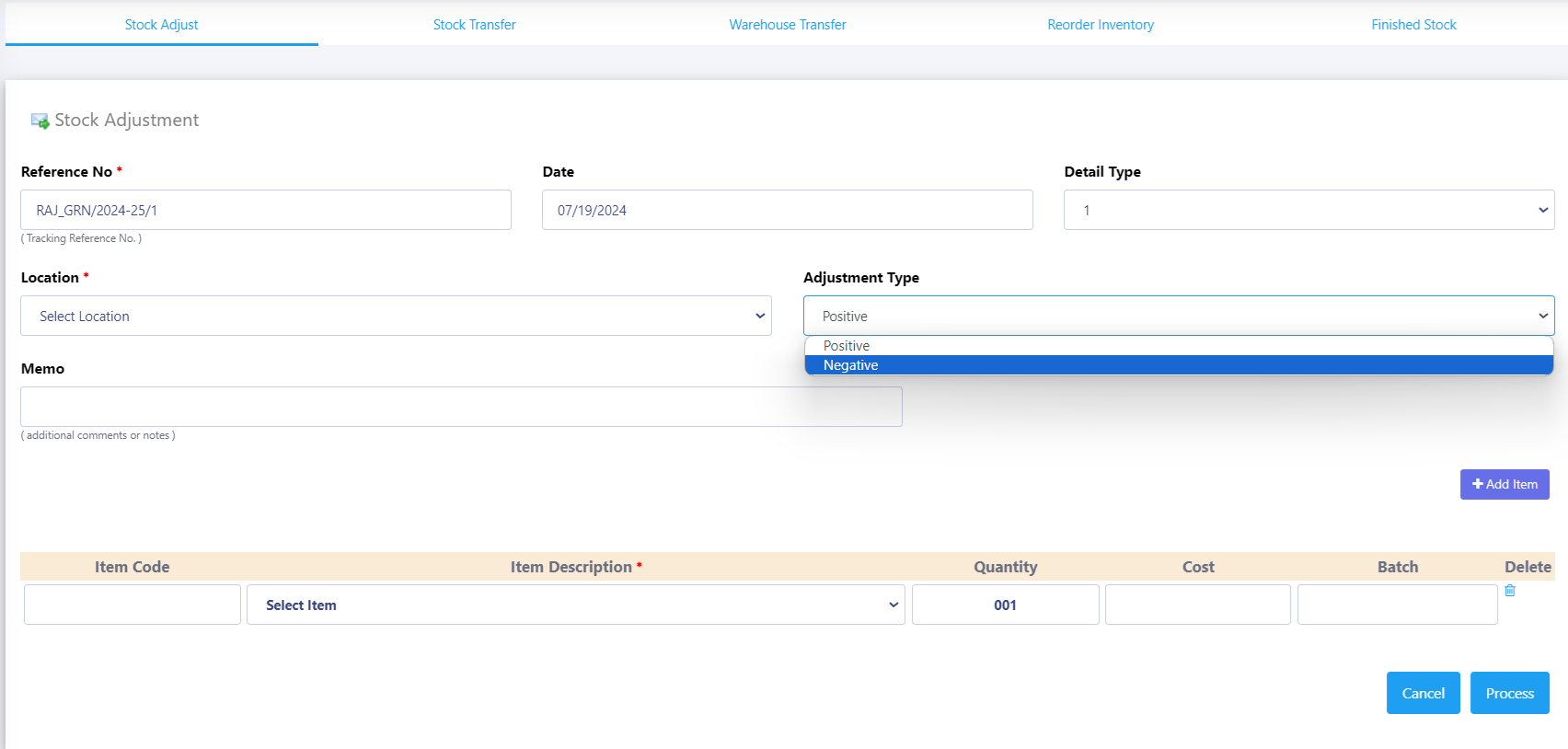

One of the characteristics of proper inventory management is ensuring that you use data and forecasting to control your purchasing procedures. This also includes identifying items by monitoring customer demand, removing obsolete stock and adjusting safety stock and reorder points.

3. Manage Supplier Relationships: It is critical to manage supply chain relationships well because you can often solve problems by working closely with suppliers. For example, suppliers can offer your business a negotiable minimum order quantity, take back products that are not selling and help you quickly restock when sales accelerate for a specific product.

4. Create Automated Reports: Since inventory control and management systems produce massive quantities of data, businesses need to find ways to analyze, report and use this data. Many systems automatically generate reports for inventory status, stock logs, reconciliation, historical stock, inventory financials.

5. Conduct a Risk Assessment: Problems regularly crop up in businesses, whether you have an unexpected sales spike, a cash shortfall, not enough warehouse space, slow-moving products or discontinued products. Prepare a risk assessment matrix to determine what your worst risks are and how you can address them when they occur.

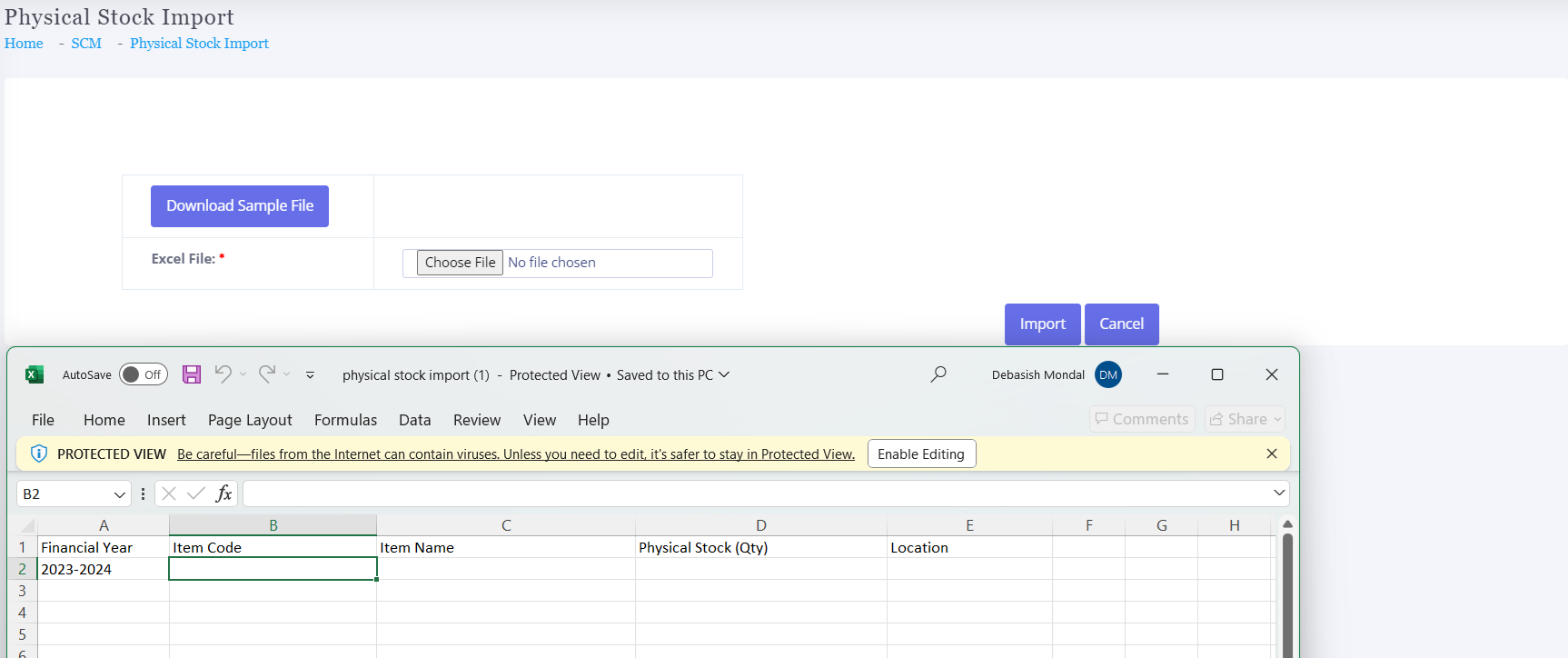

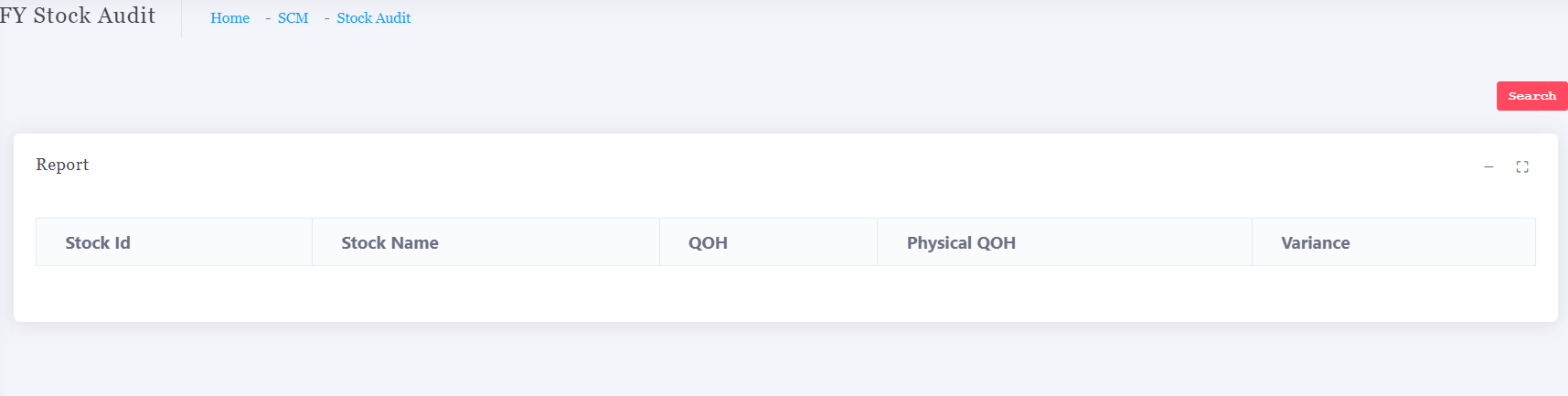

6. Regular Audit: Conduct regular audits to ensure that your actual stock and reports line up. There are three ways to perform an audit: physical goods, spot checking and cycle counting. A physical inventory requires counting all your inventory and should be performed at least annually and often at the end of the year to line up with income tax reports. Spot checking is when you choose a product or two at a different time from the full inventory, physically check it and compare it to what is in your software system. Cycle counting spreads out the reconciliation throughout the year. Each product has its audit period, but you should check high-value items more often.

7. Selective Inventory Control: Many techniques fall under selective inventory control and management or forecasting, such as ABC analysis. In this form of analysis, you classify the inventory with one of the following: usage value, procurement source, procurement difficulty, seasonality, unit price and rate of consumption.

Methods to control stock by when or how goods are ordered:

FIFO and LIFO: These are methods of placing value on the products. LIFO assumes that the goods last added to the inventory are the first goods to be sold, while FIFO assumes that the goods first added to the inventory will be the first sold.

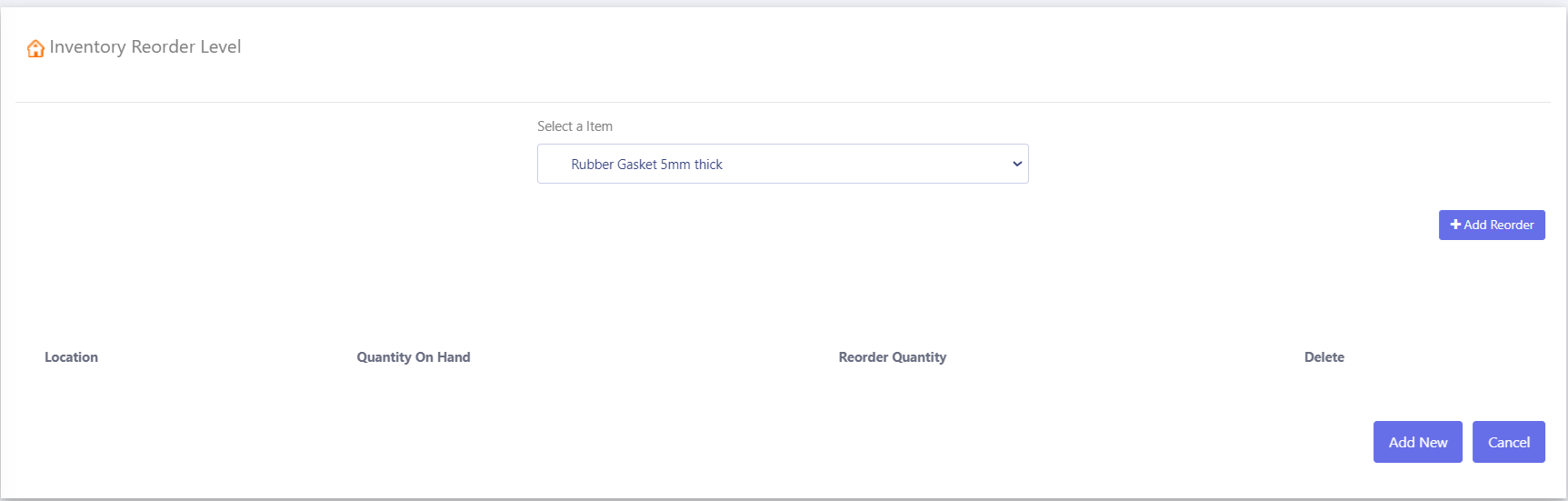

Min-Max Inventory Control: This theory sets minimum and maximum levels of stock to maintain specific items in your inventory. So, when you get to the minimum level of stock, order only enough to reach the maximum level set.

JIT Inventory: The just-in-time (JIT) inventory management strategy lines up the raw material order from suppliers with the production schedule. You decrease waste in the form of inventory cost because the goods are onsite only as needed. JIT can be a step in Lean manufacturing by slightly requiring JIT to incorporate what the customer wants in each product manufactured.

Two- or Three-Bin System: A two- or three-bin system involves two containers of the same stock item. When one container becomes empty, you use the second container (the backup), which then identifies the reorder point (ROP). The ROP is when inventory gets down to a level that initiates stock replacement activities. The problem with a method this basic is evident in situations where there are big or fast orders. You may never be exactly sure how much product is in stock at a given time, so you may not be able to predict whether you can fulfill a large order or quick, successive orders.

Fixed Order Quantity: In a fixed order quantity rule, you may only order a specific amount of an item at one time. With this rule in place, reorder mistakes, storage space issues and unnecessary expenses are kept to a minimum. You may link fixed order quantities to automatic ROPs.

Fixed Period Ordering: In a fixed period ordering rule, you link the replenishment of specific items to a particular interval. In this case, the order quantity is always different to compensate for customer demand.

Vendor-Managed Inventory: In this method, it’s often the sales representative that manages the stock on specific products, noticing and ordering what needs replenishment.

Set Par Levels: When inventory drops below the par levels, your software should signal you to order more. Par levels vary by product, relative sales rates and the time to restock and require research and sound decision-making. Par levels change over time and must be reset at regular intervals.

Further, storage costs are lower, and if your business moves fast, having only the minimum levels of stock may be more suitable.

Products

Manage products with ID, Code and detailed attributes like Product type, Category, Sub Category, Brand, Class, and Sub class etc.

Inward Stock

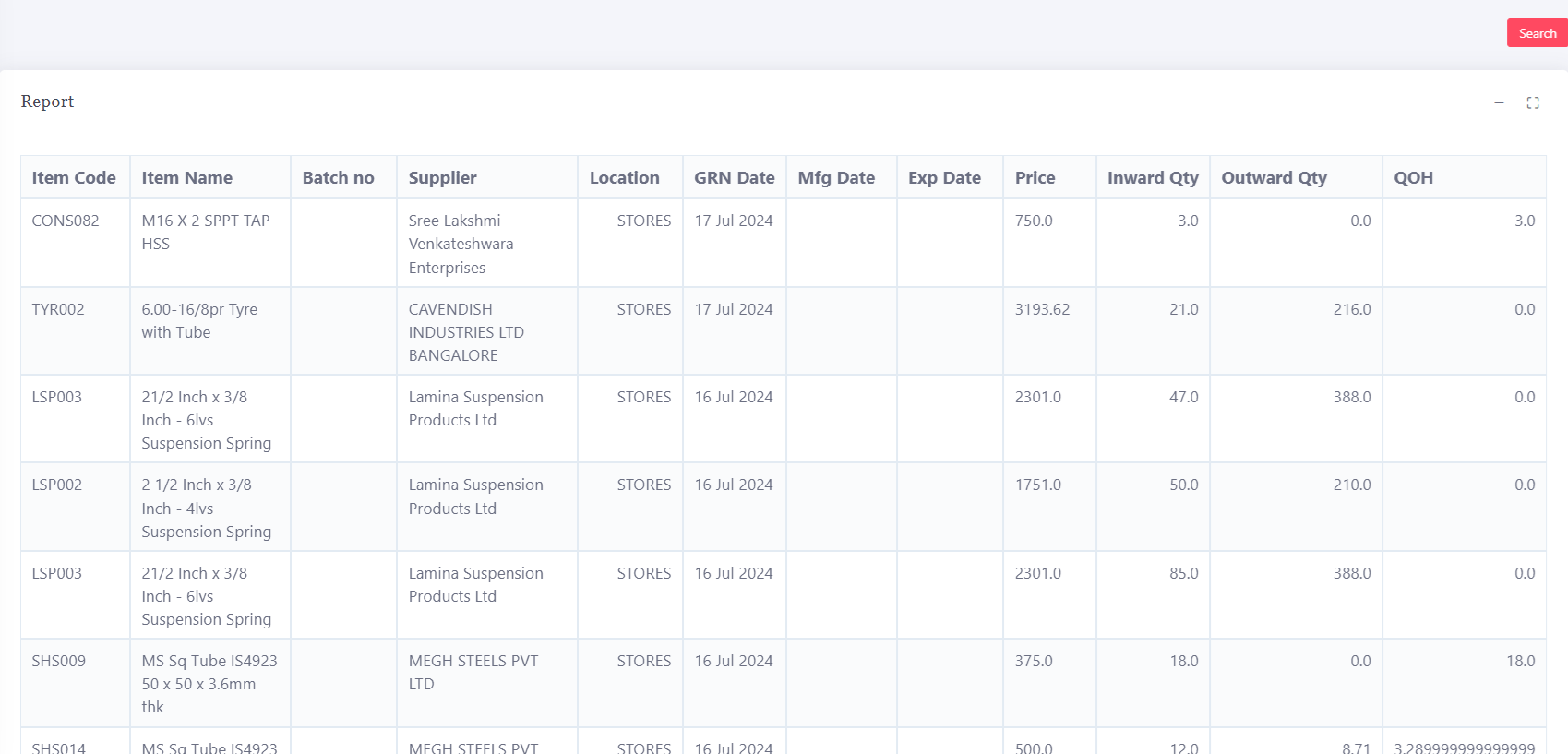

GRN of goods at any location or any other material transfer to any location creates inward inventory.

Outward Stock

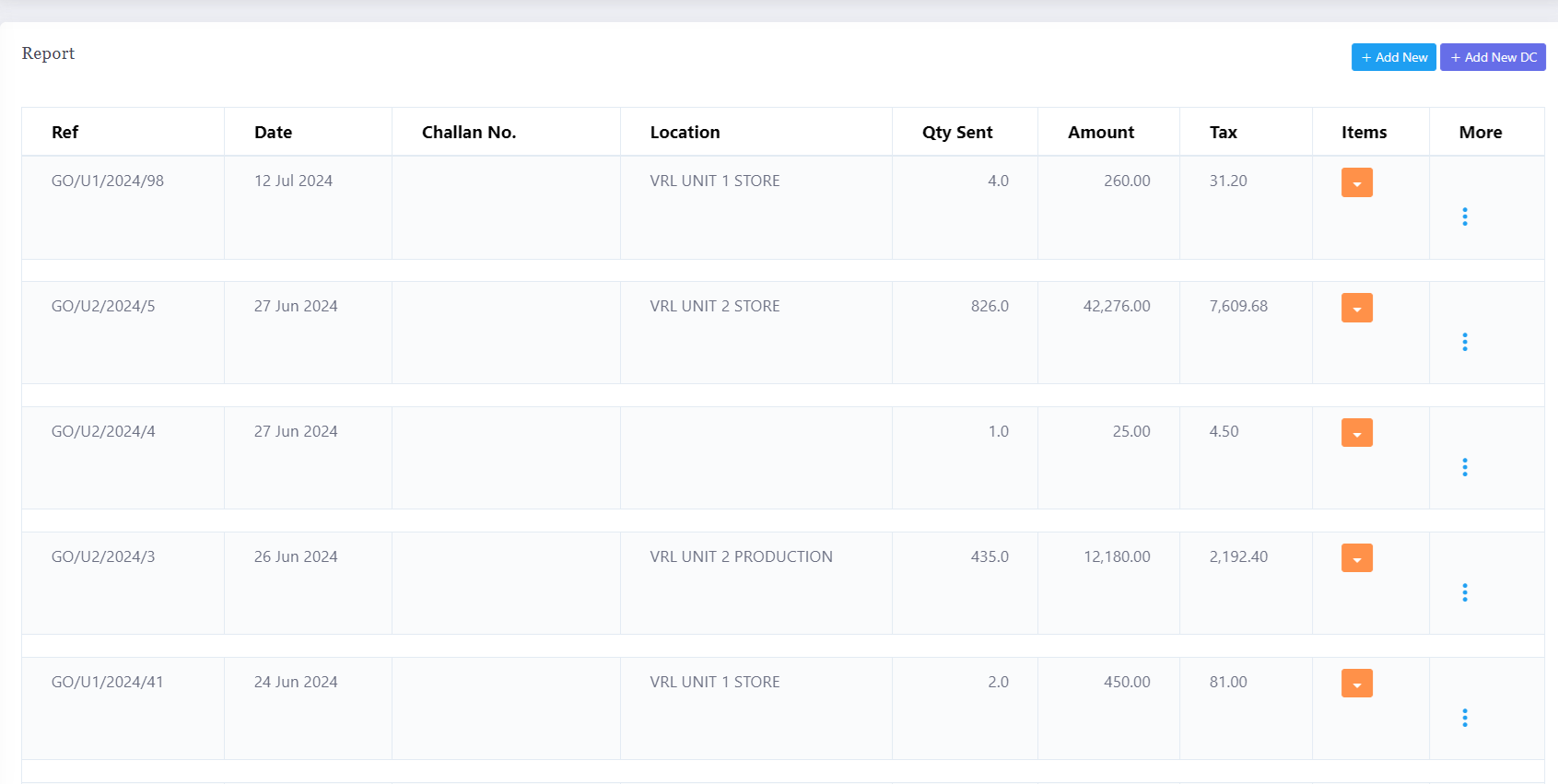

material issues, work order related stock transfer from any location or any other material transfer from any location creates outward inventory.

Locations

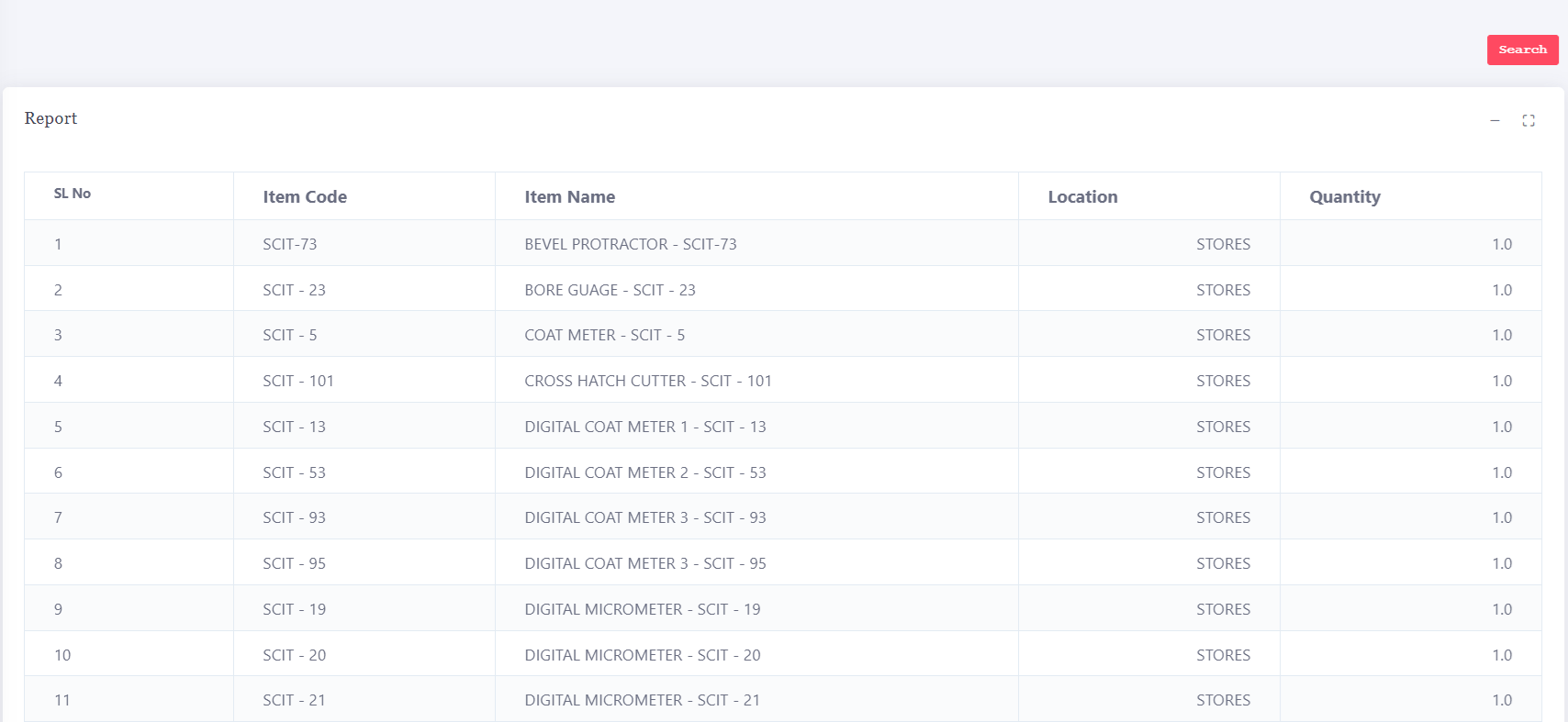

Maintain inventory across multiple locations with details of status stock in hand (QOH), stock transfer etc.

Re-Order

Manage, maintain stocks to reorder with minimum and maximum levels. View reorder reports of stocks to be ordered.

Warehouse Management

Manage, maintain stocks in warehouse in a location determined by Rack, Bin. It also manages stock movement from one warehouse, rack, bin to another warehouse, rack and bin

Reports

Stock Item

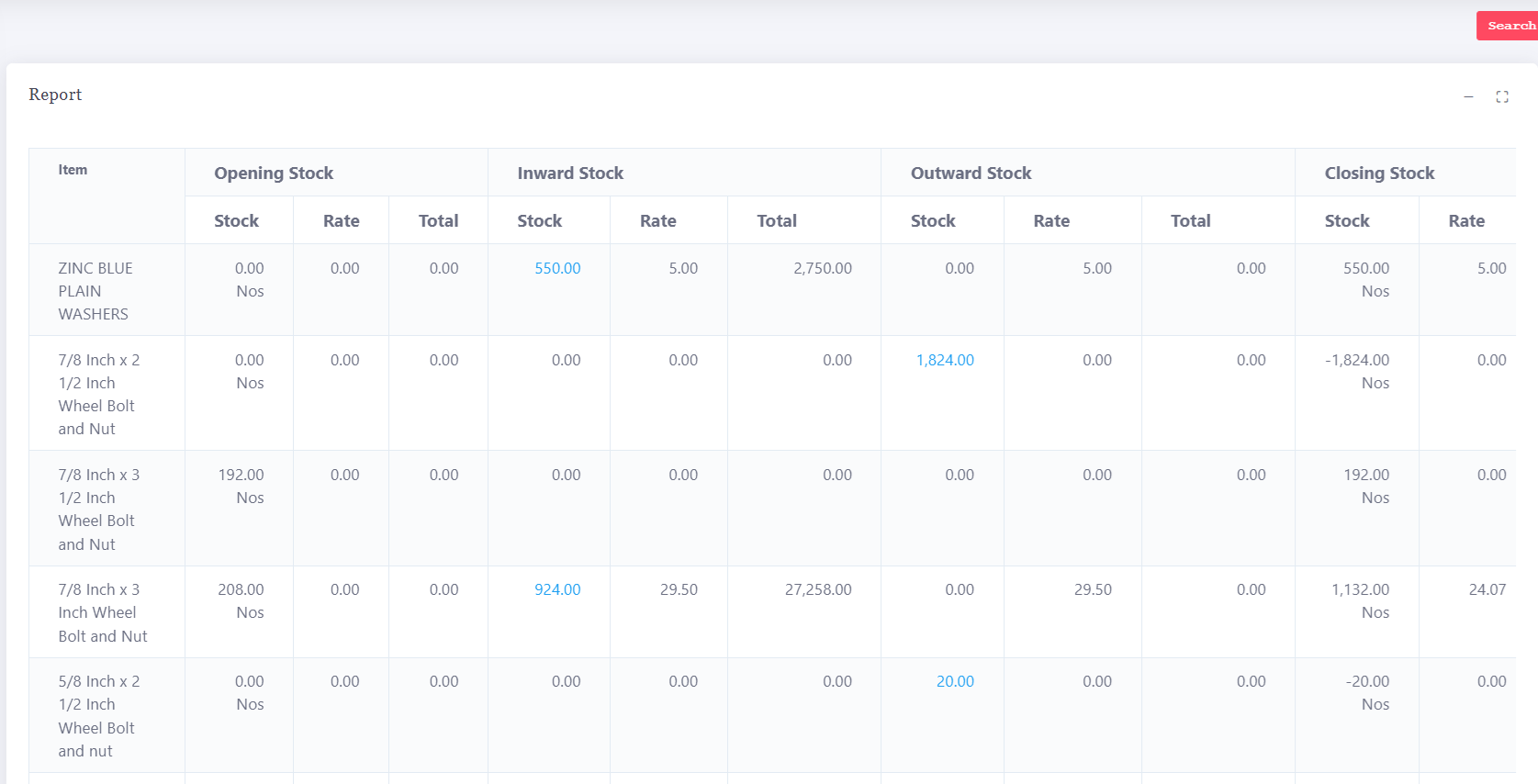

Stock Movement Analysis

Stock Summary

Stock Quantity On Hand (QOH)

Stock Inward

Stock Outward

Warehouse Movement analysis

Get Started with Peacksoft ERP Today

Intuitive solutions on cloud with integrated features like Accounting, Purchase, Sales, Production, CRM, Payroll, Inventory & Filing of all compliances. . Call us at +91-86608 58802 (M: 9845167247) to schedule a consultation.

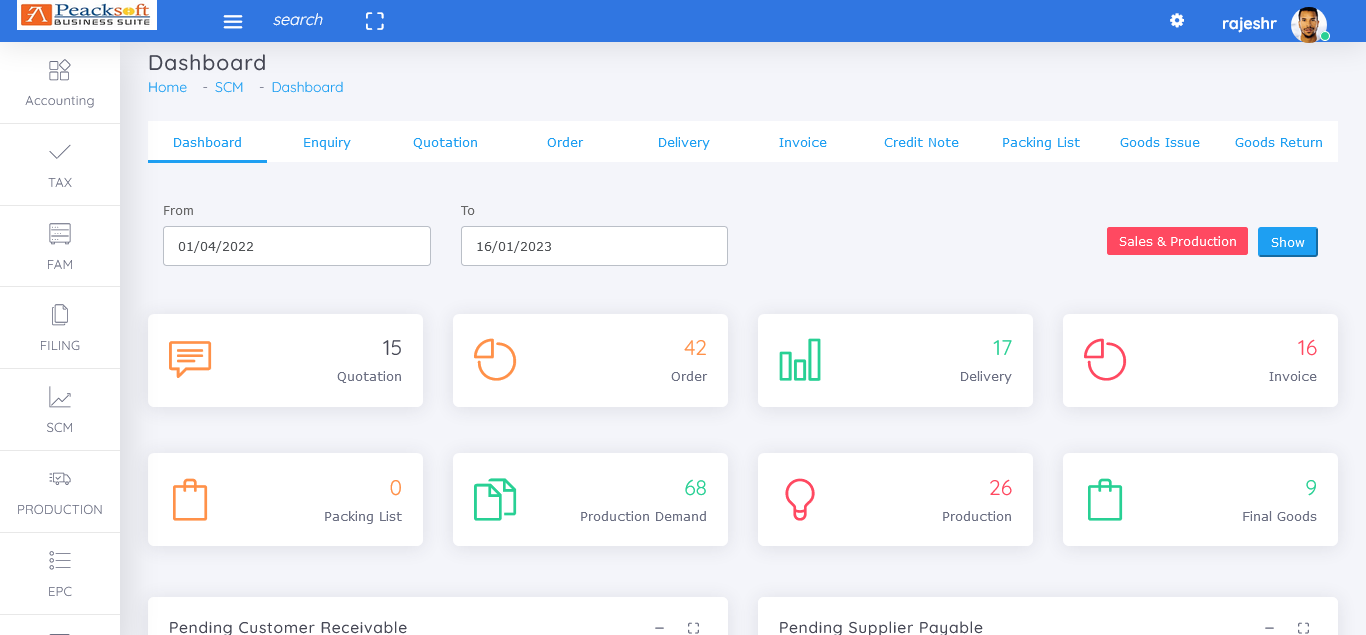

Manage sales through quotation by updating information and proceed to Sales order, Sales delivery , Sales invoice by click of few button.

Manage sales through quotation by updating information and proceed to Sales order, Sales delivery , Sales invoice by click of few button.

Manage Purchases through order by updating information and proceed to GRN, Purchase Invoice by click of few buttons.

Manage Purchases through order by updating information and proceed to GRN, Purchase Invoice by click of few buttons.

Comprehensive Inventory management features for small and mid size companies.

Comprehensive Inventory management features for small and mid size companies.

Manufacturing

Manufacturing