Peacksoft Point Of Sales

Peacksoft POS is designed to streamline sales operations, manage inventory, and handle financial transactions directly from the field. Here's how the various features you mentioned could be handled in such a system:1. Booking Sales from the Field

This feature allows field sales agents to record customer orders and process sales in real time, directly through the POS system, even when they are not at the office.

Mobile POS Integration: Sales personnel can use mobile devices to create sales orders, invoices, and receipts on the go.

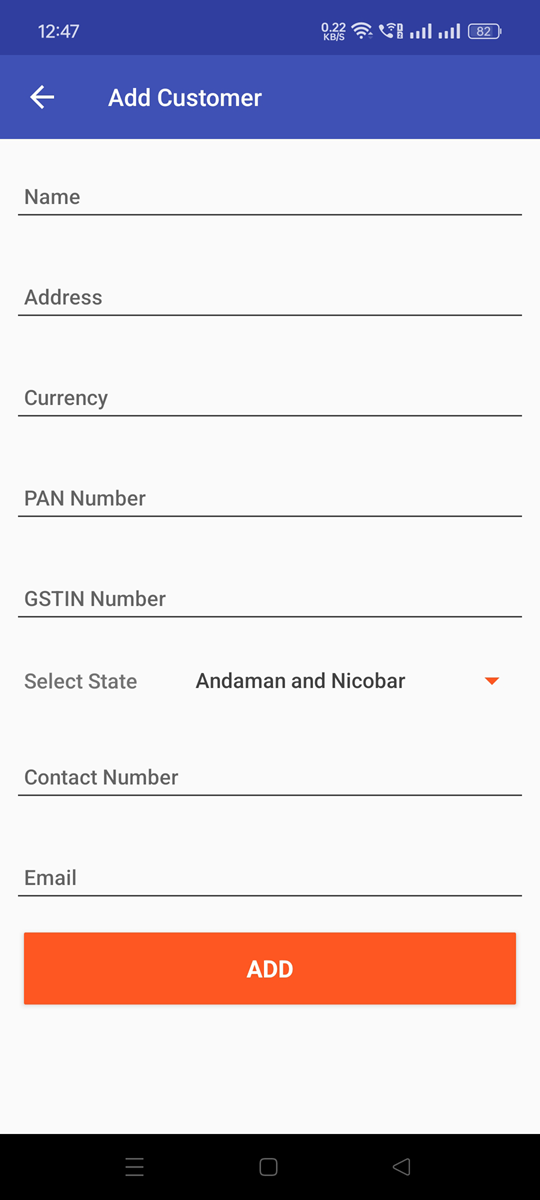

Customer Database: The system stores customer data, making it easier for sales agents to retrieve customer details for faster transactions.

Real-time Sync: Sales transactions can be instantly synced with the back-office ERP system to ensure real-time data updates for sales and finance teams.

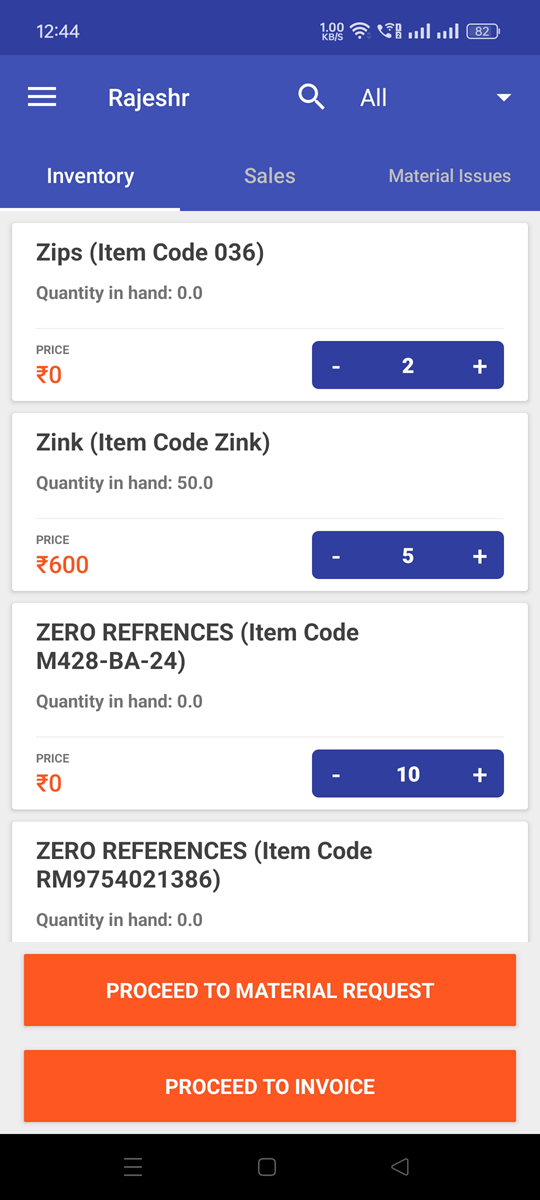

2. Checking Item Inventory

Sales agents and field personnel can check stock levels while on the field to ensure they are selling items that are available in inventory.

Real-time Inventory Data: The POS system is integrated with the inventory management module, allowing users to access real-time stock levels for specific items across different locations (warehouses, stores).

Item Availability Alerts: The system can provide notifications if an item is out of stock or low in inventory, preventing overselling.

Warehouse and Store Location Details: It can show where items are located, whether at a central warehouse or a retail store, enabling accurate stock checks.

3. Making Material Issue Requests

Field personnel may need to request materials or products for replenishment or delivery to customers. This feature allows for the creation and management of material issue requests directly from the POS system.

Material Request Form: Users can submit material requests to their company's warehouse or inventory team through the POS system.

Approval Workflow: Depending on the system’s configuration, the request may go through an approval workflow, ensuring proper authorization before processing.

Inventory Allocation: Once approved, materials can be allocated or shipped to the required location, keeping inventory levels updated in real time.

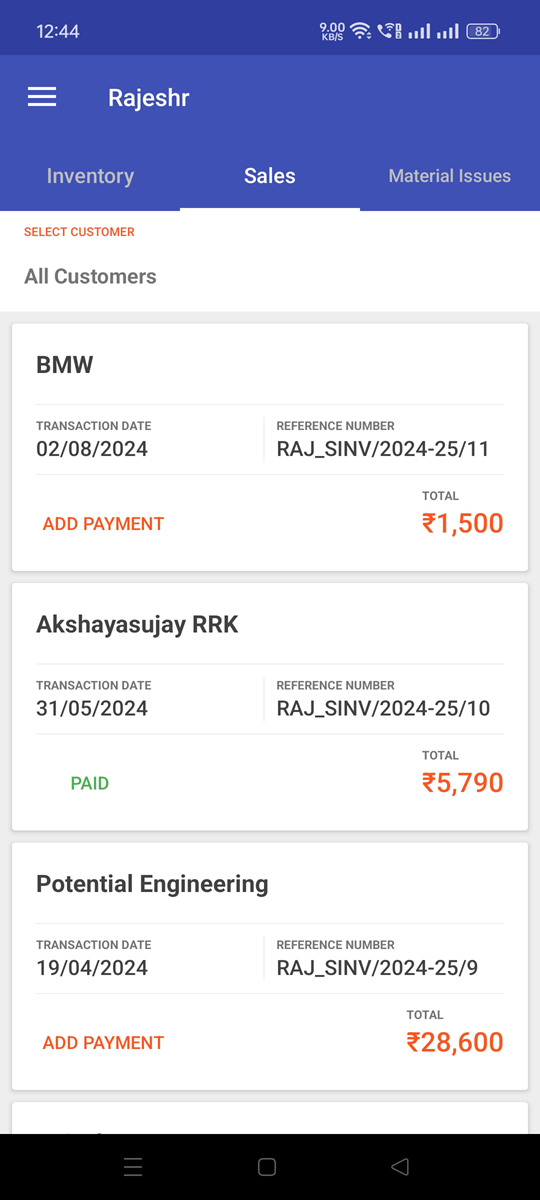

4. Booking Customer Payment Entry

The POS system can also be used to record customer payments made in the field, whether by cash, card, or other methods.

Payment Processing: Support for multiple payment types such as cash, credit/debit cards, mobile payments, or bank transfers.

Invoice Matching: Payments can be matched against the corresponding invoices, ensuring that customer balances are updated.

Payment Reconciliation: Real-time reconciliation with financial systems to update the company’s accounts and ensure accuracy in recording incoming funds.

Payment Receipts: Instant generation of digital or printed receipts for customers upon payment.

Integration with ERP

A POS system like Peacksoft would ideally integrate with a company’s ERP system to ensure seamless data flow between sales, inventory, and finance departments. This allows for real-time updates, accurate reporting, and efficient process management. Some key ERP integration points include:

Sales Orders: Sync sales data to the ERP system for order fulfillment.

Inventory Management: Reflect stock changes in the ERP’s inventory module.

Accounts Receivable: Update the company’s financials and customer accounts after payment entries.

Benefits of Peacksoft POS for Field Sales

Enhanced Productivity: Sales reps can manage all transactions in real time without needing to return to the office.

Inventory Accuracy: Field personnel can access up-to-date inventory information, reducing errors in order processing.

Faster Cash Flow: Immediate booking of customer payments helps accelerate cash flow.

Improved Customer Experience: Field reps can provide better service by booking orders, checking stock, and processing payments on the spot.

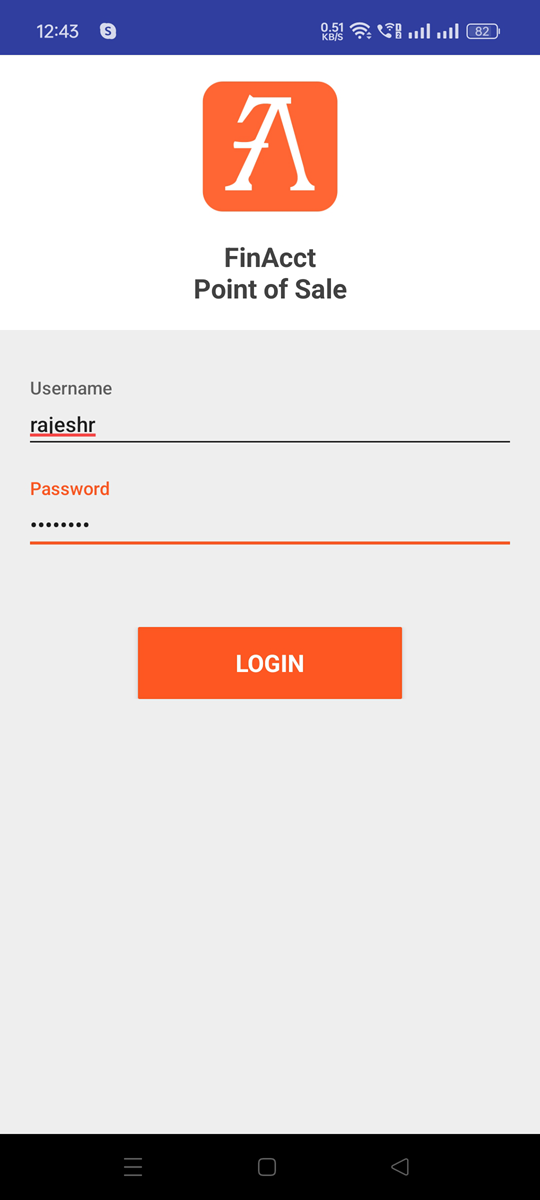

POS Login and Inventory Report

POS Inventory Checking from ERP Backend refers to the integration between a Point of Sale (POS) system and an ERP’s inventory management module, enabling real-time inventory tracking and management from the ERP backend. This ensures that sales staff, both in-store and in the field, have access to accurate inventory data for better decision-making during sales operations.

How POS and ERP Inventory Integration Works

Centralized Inventory Management:

The ERP system serves as the central repository for all inventory data. This includes details such as stock levels, product availability, location (warehouse, store, etc.), and reorder points.

The POS system, whether mobile or stationary, connects to the ERP backend, retrieving real-time inventory data when needed.

Real-time Inventory Updates:

As items are sold through the POS system, inventory levels are immediately updated in the ERP. This ensures that stock levels are accurate across all sales channels (physical store, online store, field sales).

The ERP system records stock changes, whether from sales, returns, purchases, or material issues, and reflects them across all integrated platforms.

Inventory Lookup at POS:

When making a sale or handling a customer inquiry, the POS system can request information from the ERP backend to display current inventory levels.

The ERP can show:

Current stock levels: How many units of a product are available.

Location-based inventory: Breakdown of stock across warehouses, stores, or specific locations.

In-transit items: Products that are currently being restocked but not yet available.

Reserved stock: Inventory that has been allocated for other orders or customers but not yet shipped.

Out-of-Stock and Low Inventory Alerts:

The ERP can be set to notify the POS system if an item is out of stock or if inventory is low. This prevents sales personnel from selling unavailable items and allows them to suggest alternatives.

Automatic triggers can be set for reordering inventory from suppliers once certain thresholds are met.

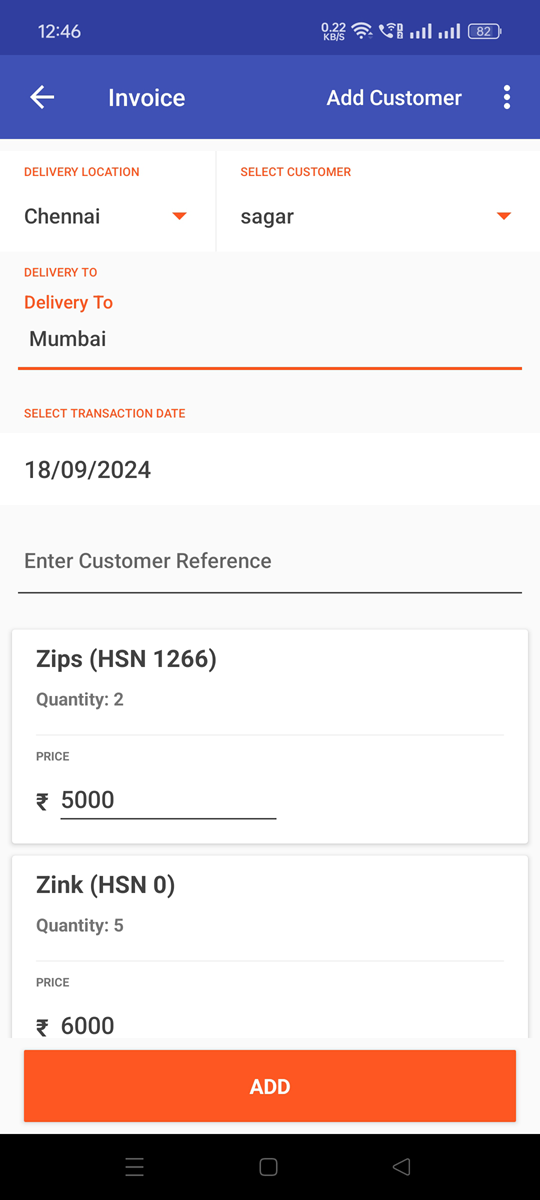

Customer Sales Invoice

POS Sales Invoice Booking refers to the process of creating and recording sales transactions through a Point of Sale (POS) system. This functionality allows businesses to generate and book invoices in real-time when a sale is made, ensuring accurate financial and inventory tracking.

Here’s how POS sales invoice booking typically works, along with the key steps and integration with the backend ERP system:

1. Sales Transaction Initiation

When a sale is initiated through the POS system, either at a retail store or in the field, the system collects details such as:

Customer Information: If the customer is registered, their details are fetched from the database. Otherwise, a new customer can be created in the system.

Items/Products Sold: The sales agent scans or selects the items purchased. The POS system retrieves product data such as descriptions, prices, discounts, and available inventory.

Payment Method: The customer chooses the payment method (cash, card, digital payments, etc.), which is processed via the integrated payment gateway.

2. Invoice Generation

After the sale is completed, the POS system generates a sales invoice. This includes:

Invoice Number: A unique identifier for the transaction.

Customer Details: Name, contact information, and possibly billing/shipping addresses.

Itemized List: All purchased items, including quantity, price, applicable discounts, taxes, etc.

Total Amount Due: The total payable amount after discounts and taxes.

Payment Method: How the payment was made (cash, credit, debit, etc.).

Tax Information: Details on applicable taxes (e.g., VAT, sales tax), depending on the jurisdiction.

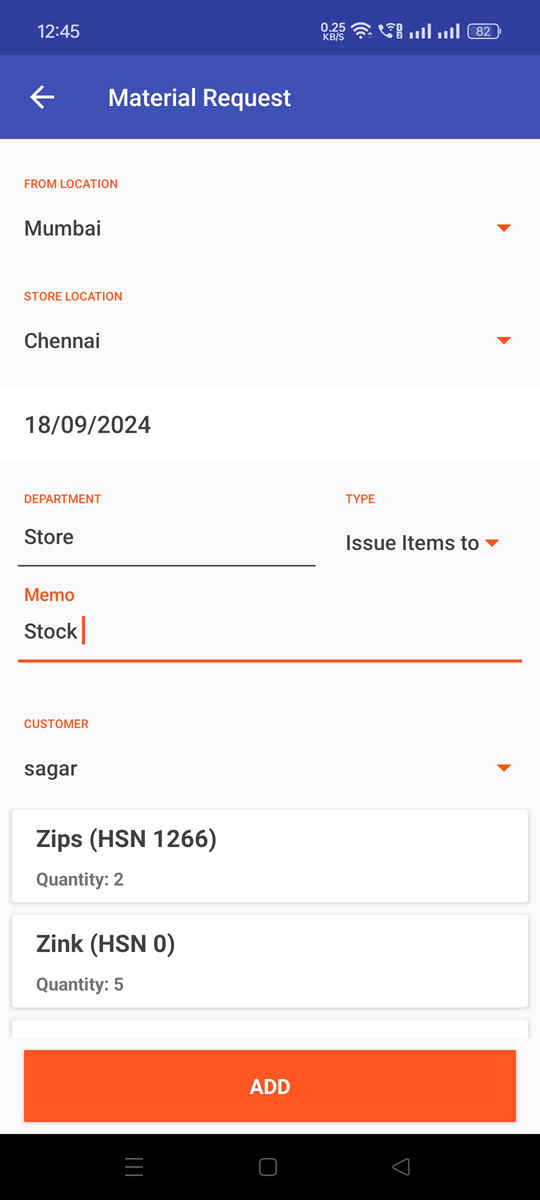

Material Issue Request

A POS Material Issue Request refers to the process of requesting materials or inventory to be moved, replenished, or allocated from the backend warehouse or storage via a Point of Sale (POS) system. This functionality is especially useful in environments where retail or field personnel need to restock items, replenish inventory at sales locations, or request materials for specific operations.

Here’s how the Material Issue Request process typically works in a POS system that integrates with an ERP’s inventory management module:

1. Purpose of Material Issue Request

The Material Issue Request through POS can be used for a variety of reasons:

Stock Replenishment: If the store or sales point is running low on inventory, the POS system allows staff to request a material issue from the warehouse or another location.

Field Sales: Field agents can request items for delivery to a client, or for personal replenishment, when selling out in the field.

Internal Transfers: Materials can be requested for internal transfers between warehouses or stores to ensure adequate stock levels in each location.

Customer Orders: If a product is unavailable at the store but is in stock at another location or warehouse, a material issue request can be created to fulfill a customer order.

2. Initiating the Material Issue Request via POS

When a salesperson or store manager identifies the need for more inventory or specific materials, they can initiate a Material Issue Request directly from the POS system.

Access Inventory Data: The salesperson checks the current stock levels in the POS system to identify items that need replenishment.

Create Material Request: The POS system will have an option to create a "Material Request" or "Stock Replenishment" form.

Item Details: The salesperson selects the items that need to be issued, specifying quantities, item codes, and any other relevant information.

Source Location: The POS system may show the source of the items (e.g., main warehouse, another store, etc.) and provide the option to choose from available stock locations.

Requester Details: Information about the store or person requesting the material is automatically included in the request.