Warehouse Management System

Peacksoft ERP's Warehouse Management System (WMS) offers advanced features that streamline warehouse operations, ensuring better management of inventory, stock locations, and supply chain activities. Key features include:

1. Stock Location Management: Peacksoft WMS allows you to manage stock locations efficiently by organizing stock into racks and bins. This feature ensures that goods are easily tracked, retrieved, and dispatched, improving picking accuracy and reducing time wastage.

2. Real-Time Inventory Tracking: The system provides real-time updates on inventory levels, helping businesses to monitor stock quantities across multiple warehouses and locations. It also integrates seamlessly with other modules like procurement, sales, and production for end-to-end visibility.

3. Automated Receiving and Dispatch: Peacksoft WMS automates the receiving of goods, creating records for items as they arrive and updating inventory levels. It also supports order fulfillment with precise dispatch processes, minimizing human error.

4. Barcode and RFID Integration: For faster processing, the system integrates with barcode and RFID technologies, enabling the scanning of items for tracking and movement updates within the warehouse.

5. Warehouse Performance Metrics: The platform provides detailed reports on warehouse activities such as inventory turnover rates, picking performance, and stock valuation, allowing for better decision-making and optimization of warehouse space.

6. Batch and Serial Number Tracking: It enables businesses to track inventory by batch numbers or serial numbers, ensuring compliance with industry regulations and enhancing traceability for products.

7. Multi-Warehouse Support: Peacksoft ERP can manage multiple warehouses from a single system, offering centralized control over stock movement and location transfers between different warehouses.

These features make Peacksoft ERP's Warehouse Management System ideal for businesses looking to improve warehouse efficiency, optimize inventory control, and reduce operational costs.

A warehouse management system (WMS) is a software solution that aims to simplify the complexity of managing a warehouse. It can provide real-time insight into inventory location and quantity. It shares data with other ERP modules or standalone software products, such as accounting software and transportation management solutions, to increase the efficiency of business operations. It also creates step by step directions to guide users through daily processes—such as receiving, picking and packing orders. Warehouse is organized in the form of warehouse location, shelves, rack/bin.

WMS Processes

- Receiving (GRN): Check in and log incoming items. Verify that you’re receiving the right quantity, in the right condition, at the right time.

- Put-away (Warehouse allocation): Move items from the receiving dock to their correct warehouse storage locations determined by warehouse, shelves, rack/bin.

- Storage (Warehouse transfer): Safely store and logically arrange inventory to enable fast and accurate picking.

- Picking: Collect the items needed in shipping/delivery plan to fulfill sales orders.

- Packing: Prepare the picked items for shipment. They must be safely packed into the correct packaging with an accurate packing slip.

- Shipping (Warehouse dispatch): Send out the finalized sales orders, ensuring that they are on the right vehicle, at the right time, with the correct documentation, so customers receive their orders on time.

Warehouse Tracking

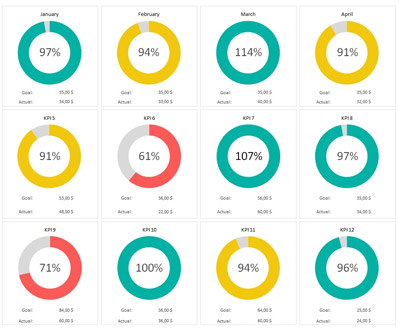

Tracking key performance indicators (KPIs) and operational statistics in a warehouse is crucial for improving efficiency and optimizing processes such as order fulfillment. Peacksoft ERP, with its advanced warehouse management features, supports this by offering reports that measure critical warehouse movements, stock status, and order fulfillment metrics.

1. Key Warehouse KPIs

Some important KPIs that help evaluate and optimize warehouse operations include:

Inventory Turnover: Measures how frequently inventory is sold and replaced over a given period. It helps assess demand planning and warehousing costs.

Order Accuracy: Tracks the percentage of orders delivered without errors, ensuring customer satisfaction by reducing returns.

Order Cycle Time: Monitors the time taken from receiving an order to its shipment, providing insights into the efficiency of picking, packing, and shipping processes.

Quantity on Hand (QOH): Reports the current stock levels for each item, helping users make informed decisions about reordering and fulfillment.

Warehouse Movement: Tracks the movement of items through the warehouse—whether they are in receiving, processing, storage, picking, or shipping areas—highlighting inefficiencies and bottlenecks.

2. Picking Strategies

Efficient picking methods in warehouse management can enhance order fulfillment speeds and accuracy:

Batch Picking: This method allows the picker to gather products for multiple orders simultaneously, which reduces travel time and increases efficiency, especially for high-demand items.

Zone Picking: The warehouse is divided into zones, and pickers are assigned specific areas. Each picker is responsible for gathering SKUs from their designated zone, optimizing workflows and reducing congestion in high-traffic areas.

First Expired, First Out (FEFO): This ensures that perishable goods, such as food or pharmaceuticals, are shipped before their expiration date, minimizing spoilage.

First In, First Out (FIFO): Prioritizes the shipment of the oldest stock, ensuring older items are moved out before newer ones, which is particularly important for non-perishable goods that may become obsolete over time.

Warehouse Movement and Location Transfers

When items are ready for picking from the warehouse's inbound (IN) area, Peacksoft ERP can guide the transfer of goods to optimal locations—based on racks, shelves, and bins closer to the packing or delivery area. This ensures that goods are efficiently staged for final shipment.

These techniques, combined with robust warehouse KPIs and effective tracking systems, allow businesses to streamline their operations, reduce errors, and enhance the overall efficiency of their supply chain management.

Peacksoft ERP provides built-in tools to implement these strategies, helping users manage stock levels, optimize picking methods, and track movement efficiently across warehouses.

Get Started with Peacksoft ERP Today

Intuitive solutions on cloud with integrated features like Accounting, Purchase, Sales, Production, CRM, Payroll, Inventory & Filing of all compliances. . Call us at +91-86608 58802 (M: 9845167247) to schedule a consultation.

Manage sales through quotation by updating information and proceed to Sales order, Sales delivery , Sales invoice by click of few button.

Manage sales through quotation by updating information and proceed to Sales order, Sales delivery , Sales invoice by click of few button.

Manage Purchases through order by updating information and proceed to GRN, Purchase Invoice by click of few buttons.

Manage Purchases through order by updating information and proceed to GRN, Purchase Invoice by click of few buttons.

Comprehensive Inventory management features for small and mid size companies.

Comprehensive Inventory management features for small and mid size companies.

Manufacturing

Manufacturing